ENGINEERED WOOD VS. SOLID HARD WOOD FLOORING

The age old quest of what wood floor is better is asked during every flooring design. Many of our clients ask us what we prefer, what is better, and what will withstand over time. The question of engineered wood versus solid hard wood flooring is almost two fold. One can be personal preference, and the other is to do with installation and ease of maintenance.

Personally at Rite-Loom we suggest engineered wood in order to give our clients that amazing wood floor look and stay within their design cost. Don’t get us wrong we absolutely love hard wood floors, the look, the feel, the colors, but you really cannot see the difference once the floor is in. Here are the differences between the two floorings so you can decide which is best for your home and your family.

Solid Hard Wood Flooring

Solid wood flooring means that each plank is made from a solid piece of wood. The thickness of the planks range from 3/8” to 1” – but the majority is ¾”

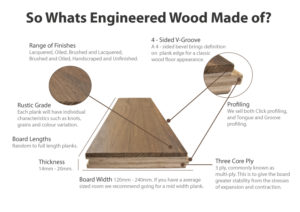

Engineered Wood Flooring

Engineered wood flooring consists of a top layer of solid wood over a multi-layer construction beneath. The top layer is known as the wear layer. The wear layer can range anywhere from .6mm to 6mm thick. The wear layer is the wood that is displayed as the finished product when it is installed within the space.

When working with our clients here at Rite-Loom we take in all the considerations of daily life and help figure out what flooring best suits their needs. We mainly suggest using engineered flooring. After some education on how the floors are made and how they can perform over time our clients tend to install engineered wood floors within their homes do to the fact there are several benefits over solid hard wood floors.

Some of the benefits of engineered wood vs. solid hard wood include:

Temperature and Humidity: Natural wood will expand and contract with the rise and fall of temperature. When this occurs the wood planks can warp, cup or buckle. Engineered wood is much less susceptible to the planks having these issues due to the multi-layer construction. Due to this construction is makes the planks more stable.

Installation: Solid wood floors usually will require subfloors that the wood will need to be nailed down to. These floors are usually not glued down because the glue will not hold down the ¾ think planks. This process takes more time and can be costly.

Engineered floors can be glued directly on a level concrete floor. This saves the homeowner costly expenses, as well as time.

Engineered wood can also have a click system that can be floated over a padding or underlayment without the use of glue or nails. This will save time in installing within the home.

Maintenance: Engineered Wood is very easy to clean and clean. Maintenance includes either a vacuum cleaner with a soft flooring attachment, or a broom. A dry microfiber dust mop can be used to pick up dirt and debris from the floor. There is also cleaner on the market that is sold specifically for engineered wood if you want to mop your floor every once in a while. Engineered wood floors can withstand water for a longer period of time than hardwood floors. The floors can scratch but for the most part will hold up to pets and kids so you do not have to be so careful and not feel like you can’t live on your floors.

Hardwood floors are similar to engineered floors as they use the same method of sweeping. The only difference is that the floors need to be regularly cleaned with a mop that is only slightly damp. Using an alcohol-based floor cleaner kit once a month or as needed is okay. Choose a cleaner you spray on and wipe off. Many love Murphy’s Oil Soap. Ask your wood dealer about using Murphy’s on the product you buy. It may not be the best for all solid wood flooring products. Hard wood floors over a number of years will also need to be sanded. There are only so many times that you can sand down the floors until you have to replace them. Also water will damage the floors if it is not cleaned up quickly, as well as dents and scratches can be made easily depending on the wood species.

Ease of installation and overall performance are the two big reasons that Rite-Loom guides our customers to quality engineered wood lines from top manufactures including Du Chateau, Kraus Hardwood, Karastan, as well as many other exclusive brands we carry. One of our greatest strengths here at Rite-Loom is to educate each of our clients on the products available to them and what will best suit their needs.